Industry News

Is Your Automatic Transmission Overheating? A Key Component You're Ignoring Could Be the Cause

Is Your Automatic Transmission Overheating? A Key Component You're Ignoring Could Be the Cause

Understanding the Hidden Dangers of Transmission Heat and How a Simple Line Can Save Your Expensive Transmission

Every day, countless drivers get behind the wheel, turn the key, and head off to their destinations, placing their complete trust in the complex machinery humming beneath them. Among the most intricate and hardworking systems in any modern vehicle is the automatic transmission. It's a marvel of engineering, performing countless gear shifts seamlessly, allowing us to navigate traffic with ease. Yet, despite its importance, it's also one of the most vulnerable and expensive systems to repair. A significant portion of premature transmission failures can be traced back to a single, relentless enemy: heat. And often, the root cause of this heat issue is a small, overlooked component: the transmission cooler line.

This article will delve into the world of automatic transmissions, exploring why they generate so much heat, the critical role of the cooling system, and why the humble cooler line is so pivotal to the health and longevity of your vehicle's transmission. We will uncover the warning signs of failure, discuss the risks of ignoring them, and explore a solution designed to address this very problem. By the end, you'll have a much clearer understanding of how to protect one of the most vital parts of your car.

The Symphony of Shifting: A Quick Look Inside Your Automatic Transmission

Before we can understand the problem of heat, we need a basic appreciation for what an automatic transmission does. Think of it as a highly sophisticated device that manages the power from your engine and delivers it to the wheels. Unlike a manual transmission where you physically select gears, an automatic does this for you, using a complex interplay of components.

At the heart of the system is the torque converter. This component acts as the link between the engine and the transmission. It uses fluid to transfer power, allowing the engine to keep running while the car is stopped (like at a red light) without stalling. Inside the transmission itself, you'll find planetary gear sets, which are clever combinations of gears that provide the different gear ratios. To engage and disengage these gears, the transmission uses clutch packs and bands, which are controlled by hydraulic pressure.

Every single one of these actions—the churning of the torque converter, the meshing of gears, the engagement of clutches—creates friction. And friction, as we know from basic physics, generates heat. In a perfect world, this heat would be minimal and easily dissipated. But in the real world of stop-and-go traffic, steep hills, and heavy loads, your transmission works hard, generating a substantial amount of thermal energy.

Transmission Fluid: More Than Just a Lubricant

If the transmission is the heart of the drivetrain, then the transmission fluid is its lifeblood. This specialized fluid serves several critical functions that go far beyond simple lubrication.

- Hydraulic Fluid: The fluid is the medium through which the transmission's computer and hydraulic system control the shifting. Pressure applied to the fluid engages and disengages the clutch packs and bands, facilitating smooth gear changes.

- Lubricant: It coats all the moving parts inside the transmission, from the gears to the bearings, reducing wear and tear caused by metal-on-metal contact.

- Coolant: This is perhaps its most crucial role in our discussion. The fluid absorbs heat generated by the transmission's internal components and carries it away to be cooled.

- Cleaning Agent: The fluid contains detergents that help keep the internal components clean by suspending tiny particles of debris and preventing sludge from building up.

Given these demanding roles, it's easy to see why the condition of the transmission fluid is so important. When fluid is fresh and clean, it performs all these jobs effectively. However, as it ages and is exposed to high temperatures, it begins to break down. This process, known as oxidation, causes the fluid to lose its viscosity (it becomes thinner), its lubricating properties diminish, and it can no longer dissipate heat efficiently. This creates a dangerous cycle: degraded fluid leads to more heat, which in turn degrades the fluid even faster, ultimately causing severe damage to the transmission's internal components.

The Silent Enemy: How Heat Destroys a Transmission

Heat is the number one killer of automatic transmissions. Operating temperatures that consistently run above 200°F (93°C) can begin to cause significant harm. For every 20°F increase above this threshold, the expected lifespan of the transmission fluid is cut in half.

So, what exactly does this heat do? The damage is widespread:

- Fluid Breakdown: As mentioned, high temperatures cause the chemical composition of the fluid to break down. It loses its ability to lubricate and cool, turning from a protective liquid into a corrosive, abrasive sludge.

- Seal and Gasket Damage: Transmissions contain numerous rubber seals and gaskets designed to keep fluid contained and pressure where it needs to be. Excessive heat causes these seals to harden, crack, and shrink, leading to internal and external leaks.

- Clutch Plate Glazing: The clutch plates inside the transmission rely on friction to engage properly. When they get too hot, the surface of the plates can become "glazed," or burned. This creates a slippery surface, causing the clutches to slip. Slipping clutches generate even more heat and lead to erratic, harsh, or failed shifting.

- Warped Components: In extreme cases, the intense heat can cause metal parts like valve bodies or even the transmission case itself to warp, leading to catastrophic failure.

The scary part is that this damage often happens silently, without any immediate warning signs. By the time you notice a problem like harsh shifting or a burning smell, significant internal damage may have already occurred. This is why proactive maintenance and a functioning cooling system are not just recommended—they are essential for preventing a multi-thousand-dollar repair bill.

The Cooling System: Your Transmission's Lifeline

To combat the relentless generation of heat, every automatic transmission is equipped with a cooling system. The most common setup involves a cooler that is integrated into the engine's main radiator. Hot transmission fluid is pumped out of the transmission, through a series of lines, and into this cooler. As it flows through a network of small tubes, the heat from the fluid is transferred to the coolant in the engine radiator, which is then cooled by the air passing through the radiator's front grille.

Once cooled, the fluid is then pumped back to the transmission to repeat the cycle. In some vehicles, particularly those used for towing or heavy-duty applications, there may also be an external, air-to-fluid transmission cooler mounted in front of the radiator for additional cooling capacity.

This entire system, however, is entirely dependent on one crucial element: the lines that connect the transmission to the cooler. If these lines fail, the entire cooling process breaks down.

The Unsung Hero: The Critical Role of the Transmission Cooler Line

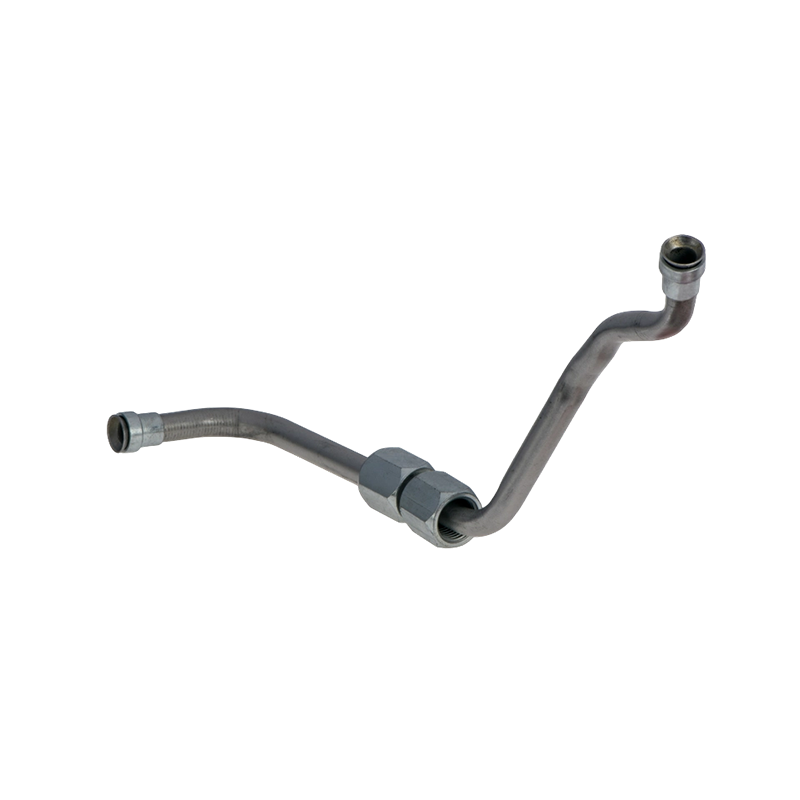

The transmission cooler lines are the arteries of the cooling system. They are tasked with carrying hot, high-pressure fluid to the cooler and returning the cooled fluid back to the transmission. These are not simple hoses; they are engineered to withstand a harsh environment.

Typically, they are constructed with a combination of high-pressure rubber or synthetic hoses and metal tubing. The metal sections provide rigidity and are routed away from hot exhaust components and sharp edges, while the flexible hose sections allow for engine movement and vibration. Over time, however, these lines can degrade.

Common causes of cooler line failure include:

- Age and Heat Cycling: Constant exposure to high temperatures and then cooling down causes the rubber to become brittle, crack, and lose its elasticity.

- Road Debris and Corrosion: The metal portions of the lines are exposed to the elements. Road salt, moisture, and gravel can cause rust and corrosion, leading to pinhole leaks. A rock kicked up by a tire can easily dent or puncture a line.

- Vibration and Chafing: Engine and drivetrain vibration can cause a line to rub against another component, slowly wearing a hole in it over time. A poorly secured line is especially susceptible to this.

- Internal Deterioration: The inside of the hose can also break down, with small pieces of rubber or lining flaking off and clogging the narrow passages of the cooler or the transmission's valve body.

When a cooler line fails, the consequences are immediate and severe. A leak means a loss of fluid. Low fluid levels lead to a drop in hydraulic pressure, causing slipping, harsh shifts, and, eventually, a complete inability to move. Furthermore, with little to no fluid circulating, the transmission will overheat catastrophically in a matter of minutes, often resulting in irreparable damage.

A Solution for Lasting Performance

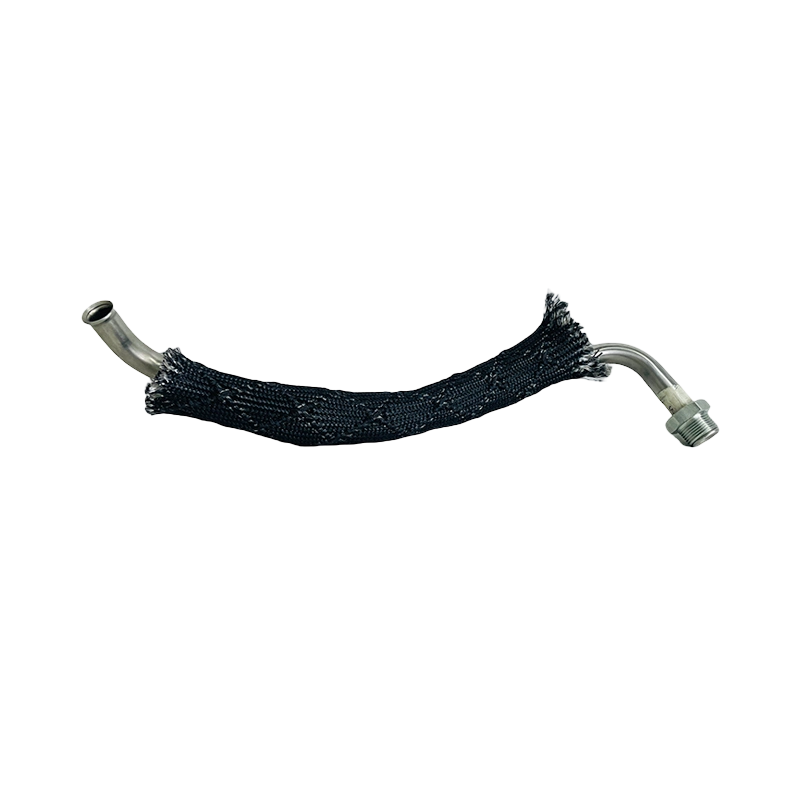

Recognizing the critical nature of this component, it is vital to choose a replacement part that meets or exceeds the original specifications. A solution designed to address these issues is the Enhance Transmission Longevity with a Precision-Engineered Cooler Line Assembly (OE# 1L3Z-18663-AB). This assembly is a direct replacement, engineered to provide a leak-free and durable connection for the transmission cooling system.

Such a replacement part is built with the specific pressures and temperatures of the application in mind. It is designed to replicate the form and function of the original equipment, ensuring a straightforward installation without the need for modifications or special adapters. This focus on precision engineering helps to guarantee that the fluid can flow freely and safely between the transmission and the cooler, maintaining the correct operating temperature and preventing the kind of overheating that leads to premature wear. By ensuring a reliable and leak-free path for the transmission fluid, this component plays a direct role in safeguarding the health of the entire transmission system.

Comparing Replacement Options: Making an Informed Choice

When faced with a leaking cooler line, vehicle owners have several options. Understanding the differences between them is key to making a wise decision for the long-term health of your vehicle.

| Feature | OEM (Dealer) Part | Universal/Generic Hose | Precision-Engineered Replacement |

|---|---|---|---|

| Fitment | Guaranteed to fit perfectly as it's the original part. | Requires cutting, flaring, and fitting. Prone to leaks and improper routing. | Designed as a direct, bolt-on replacement, matching OEM dimensions and routing. |

| Material Quality | Matches the original factory specifications. | Variable. May not be rated for the specific pressure and temperature of the application. | Constructed with materials that meet or exceed OE standards for durability and heat resistance. |

| Installation | Straightforward for a mechanic, but can be costly due to parts markup. | Complex and time-consuming. Requires special tools and a high level of skill. | Simple and quick for a DIYer or mechanic, as it's designed to match the original part's placement. |

| Long-Term Reliability | High, but at a significant purchase cost. | Low. Improper fit and material issues often lead to premature failure. | High. Engineered for dependable, leak-free operation over the long term. |

| Cost | Typically the most expensive option. | Low initial material cost, but high labor cost and risk of future failure. | A balanced cost, offering good value without the high price of a dealer part. |

As the table illustrates, while a universal hose might seem like an inexpensive fix in the short term, it carries significant risks. The time, labor, and potential for a faulty installation often outweigh the initial savings. An OEM part is a safe bet but comes with a hefty price tag. A precision-engineered replacement offers a compelling middle ground, providing OEM-level fit and reliability at a more accessible price point.

Recognizing the Warning Signs of a Failing Cooler Line

Early detection is your best defense against a catastrophic transmission failure. Being proactive and knowing what to look for can save you from a major headache and a huge expense. Here are the common warning signs that your transmission cooler lines may be in trouble:

- Visible Fluid Leaks: This is the most obvious sign. Transmission fluid is typically bright red, though it can be reddish-brown or dark brown if it's old and dirty. If you see puddles or drips of this fluid under your car, especially towards the front or middle of the vehicle, you have a leak. Check the ground where you park regularly.

- Burning Smell: Transmission fluid has a distinct sweet or tart smell. If you notice a burning odor while driving or after you park, it could be overheating transmission fluid dripping onto hot engine or exhaust components. This is a serious warning sign.

- Low Transmission Fluid Level: If you check your transmission dipstick (if your vehicle has one) and find the level is consistently low, and you don't see any leaks from the transmission pan or axle seals, the cooler lines are a prime suspect.

- Transmission Slipping or Harsh Shifting: A low fluid level caused by a leak will lead to a drop in hydraulic pressure. This can manifest as the engine revving up between gear changes (slipping) or as sudden, jarring, or delayed shifts.

- Overheating Warning Light: Some vehicles have a specific transmission temperature warning light. If this illuminates, pull over and stop driving as soon as it is safe to do so. Continuing to drive with an overheating transmission can cause irreversible damage in minutes.

Maintenance and Inspection: A Proactive Approach

You don't have to wait for a problem to appear. A simple visual inspection can be part of your regular routine, such as when you're checking your oil or washing your car.

How to inspect your transmission cooler lines:

- Ensure Safety: Park on a level surface, engage the parking brake, and let the engine cool down completely. Hot transmission fluid is under pressure and can cause severe burns.

- Locate the Lines: Open the hood and trace the lines from the side of the transmission (usually on the driver's or passenger's side) up towards the radiator. You'll see two lines—one for the hot fluid going out, and one for the cool fluid coming back.

- Check for Leaks: Look carefully along the entire length of both lines. Pay close attention to the connections at each end and where the rubber hoses meet the metal tubing. Look for any signs of wetness, seepage, or drips.

- Inspect for Damage: Check the metal parts for signs of rust, corrosion, or any dents or kinks. Examine the rubber hoses for cracks, bulges, fraying, or any signs of chafing where they might be rubbing against another part.

- Feel the Hoses (When Cool): Gently squeeze the rubber sections. They should feel firm but supple. If they feel brittle, mushy, or crunchy, it's a sign that they are deteriorating from the inside out.

If you spot any of these issues, it's time to replace the lines. Don't wait for a small leak to become a catastrophic failure.

Frequently Asked Questions About Transmission Cooler Lines

Q: Can I just use a piece of standard rubber hose and a couple of clamps to fix a leak?

A: This is strongly discouraged. Transmission cooler lines are high-pressure hoses designed to handle temperatures that can exceed 300°F. Standard heater or radiator hose is not built for this kind of application and will likely burst, leading to a rapid and total loss of fluid. It's a risky shortcut that can result in far more expensive damage.

Q: How difficult is it to replace a cooler line assembly myself?

A: For someone with moderate mechanical skills, it can be a manageable DIY job. The main challenges are often accessing the fittings, which can be in tight spaces, and dealing with rusted-on bolts. You will need to drain the transmission fluid first and then refill it after the replacement is complete. If you are not comfortable working under a vehicle or with fluid systems, it's a job best left to a professional mechanic.

Q: How long do transmission cooler lines typically last?

A: There is no set lifespan, as it depends heavily on the climate, driving conditions, and exposure to road salt. However, on average, you can expect them to last anywhere from 80,000 to 150,000 miles. In regions with harsh winters and heavy road salt use, they may fail sooner.

Q: What happens if all my transmission fluid leaks out while I'm driving?

A: This is a worst-case scenario. You will likely experience a complete loss of propulsion as the transmission can no longer engage gears. More importantly, the internal components will be starved of lubrication and will quickly destroy themselves from friction and heat. If you suspect a sudden and major leak, pull over safely and shut the engine off immediately. Do not attempt to drive the vehicle any further. Arrange for a tow truck.

Conclusion: A Small Part with a Big Responsibility

Your automatic transmission is an investment, and protecting it should be a priority. While we often think of major components like the engine or the transmission itself, we must not forget the supporting cast that keeps everything running smoothly. The transmission cooler line is a prime example of a small, unassuming part that carries a huge responsibility.

It is the critical link in the chain that dispels the heat that threatens your transmission's very existence. A failure in this single line can cascade into a complete and catastrophic breakdown. By understanding its function, recognizing the signs of its failure, and choosing a high-quality, precision-engineered replacement when the time comes, you are taking a proactive and intelligent step toward ensuring the health and longevity of your vehicle.

Don't let a preventable issue like a faulty cooler line leave you stranded with a massive repair bill. Pay attention to the warning signs, perform regular checks, and invest in quality parts. Your transmission will thank you for it with thousands of miles of reliable, smooth-shifting performance.

Content

- 1 Understanding the Hidden Dangers of Transmission Heat and How a Simple Line Can Save Your Expensive Transmission

- 1.1 The Symphony of Shifting: A Quick Look Inside Your Automatic Transmission

- 1.2 Transmission Fluid: More Than Just a Lubricant

- 1.3 The Silent Enemy: How Heat Destroys a Transmission

- 1.4 The Cooling System: Your Transmission's Lifeline

- 1.5 The Unsung Hero: The Critical Role of the Transmission Cooler Line

- 1.6 A Solution for Lasting Performance

- 1.7 Comparing Replacement Options: Making an Informed Choice

- 1.8 Recognizing the Warning Signs of a Failing Cooler Line

- 1.9 Maintenance and Inspection: A Proactive Approach

- 1.10 Frequently Asked Questions About Transmission Cooler Lines

- 1.11 Conclusion: A Small Part with a Big Responsibility

Our Main Products

Contact Us

Contact Us

+86-138 0586 3066

+86-574 8840 6311

Send An E-mail

Send An E-mail

Mobile

Mobile

Copyright ?NINGBO JIATIAN AUTOMOBILE PIPE CO.,LTD. All Rights Reserved.

English

English