Engine Coolant Thermostat Housing

Engine Coolant Thermostat Housing

Engine Coolant Thermostat Housing

information to be updated

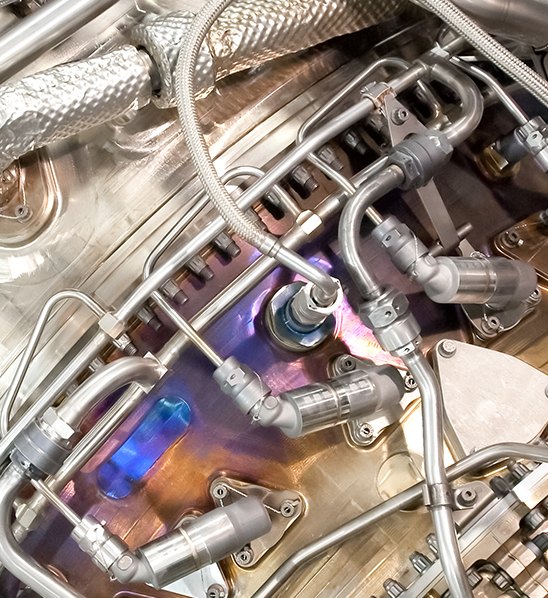

The Engine Coolant Thermostat Housing is a core component in the engine cooling system. It is a housing fixed to the engine that houses the thermostat and serves as the fluid channel and connection point for coolant circulation between the engine and radiator.

Product Features:

It provides a precise mounting location for the thermostat, enabling it to accurately sense coolant temperature and initiate opening and closing operations.

It acts as a switching station between the engine's small circuit and the radiator's large circuit, controlling coolant flow based on thermostat action, ensuring the engine quickly reaches and maintains optimal operating temperature.

Made of heat-, pressure-, and corrosion-resistant materials, it ensures long-term reliability under harsh operating conditions.

It features precise sealing surfaces and mounting structures, and works with gaskets or seals to prevent coolant leaks.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Engine Coolant Thermostat Housing: The Core Hub for Intelligent Temperature Control in Cooling Systems

Within an automotive engine cooling system, the Engine Coolant Thermostat Housing is a critical functional component. It serves not only as the precise housing for the thermostat but also as the core channel and switching hub for coolant circulation between the engine and the radiator. The reliability of its design and manufacturing directly impacts whether the engine can operate efficiently and stably within its optimal temperature range. Leveraging decades of deep manufacturing expertise in automotive tubing components, JIATIAN is committed to producing high-quality thermostat housings that meet the demanding requirements of rigorous operating conditions.

Core Functions and Role

This housing primarily fulfills three core functions:

-

Precision Housing: Provides an accurate and secure mounting location for the thermostat, ensuring the sensitivity and operational accuracy of its temperature-sensing element.

-

Flow Path Switching: Acts as the switching valve between the coolant's minor and major circuits. During a cold start, it directs coolant through the "minor circuit" within the engine block for rapid warm-up. Upon reaching operating temperature, it switches—as commanded by the thermostat—to the "major circuit" involving the radiator to maintain thermal stability.

-

Pressure Containment and Sealing: Forms part of the cooling system's pressurized circuit. It must provide reliable sealing to prevent coolant leakage and withstand system pressure and pulsations during operation.

Key Performance Attributes and Product Highlights

| Performance Dimension | Specification and Requirements | JIATIAN's Solution |

|---|---|---|

| Material Science & Durability | Must withstand long-term exposure to hot coolant, anti-freeze chemicals, system pressure, and thermal cycling stress. | Utilizes high-strength, heat-resistant, corrosion-resistant engineering plastics (e.g., reinforced nylon) or aluminum alloys, ensuring dimensional stability and material integrity over the long term. |

| Precision Forming & Sealing | Complex internal channels require smooth surfaces to reduce flow resistance; all mating surfaces (e.g., interfaces with engine, thermostat, hoses) must guarantee absolute sealing. | Employs advanced hydraulic internal forming and hydroforming technologies (capable of processing parts up to 1.5m in length, diameters φ10-φ80mm) to ensure channel accuracy. Combined with high-precision machining centers, we create perfect sealing surfaces and ensure strict compatibility with high-quality gaskets/seals. |

| Structural Integration & Lightweighting | Modern designs often integrate multiple coolant ports and sensor mounts into a single unit, while also demanding reduced weight. | Achieves integration through unified design and manufacturing, reducing connection points and leakage risks. Structural optimization enables lightweighting, aligning with modern engine design trends. |

| Manufacturing & Quality Control | Consistency in mass production is paramount, as any defect can lead to system failure. | Relies on automated equipment including 10 CNC automatic tube benders, laser welders, and welding robots to ensure production consistency. Our in-house comprehensive laboratory subjects products to rigorous pressure testing, leak testing, and material performance validation. |

Why Choose JIATIAN's Thermostat Housing?

JIATIAN extends its leading-edge technology from automotive bellows and tubing manufacturing to the production of critical components like the thermostat housing. We provide not just products, but solutions based on profound engineering experience:

-

Technical Heritage: Manufacturing expertise dating back to 1995 ensures a deep understanding of processing techniques for both metals and engineering plastics.

-

Advanced Manufacturing Capabilities: We control the entire process from raw material to finished product, utilizing a full range of advanced equipment (e.g., 800T hydraulic hydroforming machines, automatic laser welders, large machining centers), enabling complete control from R&D to processing.

-

Quality Commitment: We are dedicated to creating world-leading automotive tubing products. Every Engine Coolant Thermostat Housing undergoes stringent testing to ensure excellent performance under various extreme conditions, safeguarding reliable engine operation.

Frequently Asked Questions

Q1: What is the most common failure for a thermostat housing? How can it be identified?

A1: The most common failure is?coolant leakage?from interfaces or sealing surfaces due to aging or stress corrosion. Identification methods include: checking for pink or green coolant residue around the housing; unexplained rapid drop in coolant level; or detecting a sweet smell in the engine bay.

Q2: Does a thermostat housing require regular replacement?

A2: It is not a routine wear-and-tear item. However, its service life is influenced by material, operating environment, and coolant quality. It is generally recommended to inspect the housing for aging, cracks, or deformation when replacing the thermostat or during major engine overhaul, and replace it as needed. Using a high-quality?JIATIAN Thermostat Housing?can significantly extend the reliable service life of this component.

Q3: Which is better, a plastic housing or an aluminum housing?

A3: Both have advantages.?Engineering Plastic Housings?are lightweight, cost-effective, and offer excellent corrosion resistance, making them a common choice for modern engines.?Aluminum Housings?provide high strength and superior high-temperature resistance, often used in high-performance or severely stressed engines. JIATIAN offers professional manufacturing solutions for both materials based on customer design specifications and performance requirements.

Q4: What is the most important consideration when replacing a thermostat housing?

A4:?Cleanliness and sealing?are paramount. The engine mating surface must be thoroughly cleaned, ensuring no old gasket residue or debris remains; new, specified gaskets or seals must be used; and bolts must be tightened evenly to the manufacturer's specified torque and sequence to prevent distortion or leaks due to uneven force.

English

English