Engine Oil Cooler Line

Engine Oil Cooler Line

Engine Oil Cooler Line

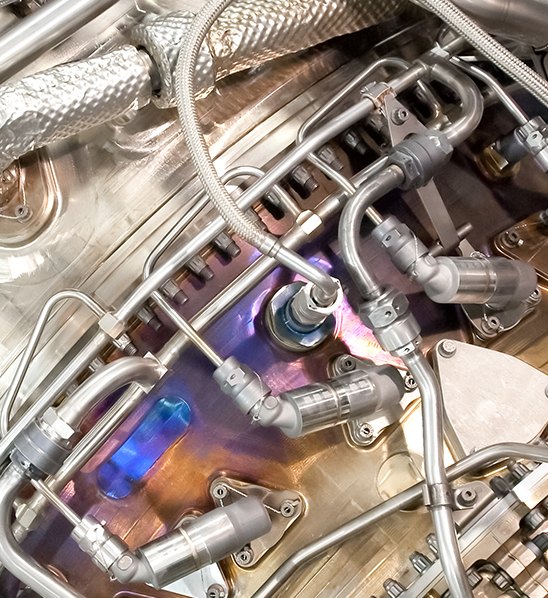

The Engine Oil Cooler Line is a key component in the engine's lubrication system. It transports hot oil generated by engine operation to the oil cooler and, after cooling, directs it back into the engine. This assembly, comprised of high-pressure, high-temperature, and oil-corrosion-resistant hoses or rigid metal tubes, ensures that the oil temperature remains within the engine's optimal operating range, thereby protecting engine components and extending their life.

Product Features:

Integrated Kit: Includes oil-resistant hose, braided steel tubing, quick-release clamps, and 10AN/12AN fittings for one-time replacement, saving time and effort.

Leak-proof Seal: Equipped with O-ring or bellows ends, it provides a leak-free, reliable seal and maintains stable system pressure.

Multi-Vehicle Compatibility: Compatible with engines and transmissions from multiple brands, directly replacing original equipment parts.

Vibration-Resistant Structure: The braided steel tubing and metal clamps provide vibration and shock resistance, making it suitable for heavy-duty, off-road, and commercial vehicles.

Lightweight Design: Utilizes high-strength, lightweight aluminum alloy or composite materials to reduce overall weight and improve fuel economy.

Easy Installation: Threaded or snap-on quick connectors, combined with dedicated clamps, allow for easy installation without the need for additional tools or modifications.

Versatile Compatibility: Compatible with oil coolers, oil filters, pressure regulators, and other components to support various oil cooling needs for engines, transmissions, power steering, and more.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

In the harsh operating environment of an engine, uncontrolled oil temperature is a core risk that can lead to lubricant failure, abnormal component wear, and even engine seizure. Traditional rubber hoses are prone to aging and bursting under high temperature and pressure, while ordinary metal tubes struggle with continuous vibration and thermal stress, creating reliability weak points in the lubrication system.?JIATIAN Engine Oil Cooler Line Assemblies?are the?high-performance integrated solution?born to solve this industry challenge. We utilize precision manufacturing technology to build reliable high-temperature fluid transfer channels from the engine to the cooler, ensuring the lubrication system operates consistently within its optimal temperature range.

?

I. Basic Understanding:

Oil cooling lines are not simply connecting pipes; they are core circulating components of the engine lubrication system, playing a crucial role as heat exchange carriers.

Definition: Oil cooling lines are dedicated piping assemblies connecting the engine oil passages to the oil cooler. They are responsible for delivering high-temperature engine oil to the cooler for cooling and then guiding the cooled oil back to the engine, forming a closed-loop temperature management system.

Core Functions: Actively regulates oil temperature, preventing lubrication failure and sludge formation due to excessively high oil temperatures, or poor flow and increased wear during starting due to excessively low oil temperatures.

Consequences of Failure: Leaks in the lines can lead to decreased oil pressure and insufficient oil volume, causing serious mechanical failures such as cylinder scoring and bearing damage. Blockages or poor flow in the lines directly result in heat dissipation failure and engine overheating.

Direct Relationship with JIATIAN Products: Every one of our oil cooling lines is designed and manufactured according to OEM-level safety standards. Its basic characteristics of high pressure resistance, high temperature resistance, and oil corrosion resistance are the first and most important line of defense against the above-mentioned systemic risks.

2. Core Technologies:

A high-quality oil cooling system must excel in a series of stringent physical and chemical indicators. The table below summarizes the key industry indicators and their corresponding technical aspects in JIATIAN products:

| Core Technical Indicator | Industry Requirement & Challenge | JIATIAN Solution & Product Advantage |

|---|---|---|

| Pressure Resistance | Must withstand system pulsating pressure (typically 4-8 Bar) and peak pressure. Rubber hoses can bulge; inferior metal tubes may crack. | Utilizes?multi-layer high-tensile stainless steel braiding?or?precision hydroformed metal bellows. Burst pressure far exceeds operating pressure, easily handling pressure spikes. |

| Temperature Resistance & Thermal Stability | Long-term exposure to 80-150°C hot oil, with potential higher spikes. Materials must resist aging and deformation. | Inner liner uses?specialty FKM or HNBR rubber; outer layer has high-temp protection. Metal parts use?premium stainless steel or aluminum alloy, ensuring stability from -40°C to 200°C. |

| Vibration & Fatigue Resistance | Constant engine vibration can loosen fittings and cause metal fatigue cracks in tubes. | Unique bellows structure or vibration-dampening braided layers?effectively absorb and dissipate vibrational energy. Combined with?anti-loosening quick-connect fittings or clamps, they achieve a fatigue life far exceeding ordinary rigid tubes. |

| Sealing Reliability | Connection points are high-risk areas for leaks. Flat seals can fail under thermal cycling. | Standard?O-ring seals?or?metal ball/cone seal?structures utilize elastic compensation and precision mating to ensure?zero leakage?despite thermal expansion and contraction. |

| Fluid Compatibility & Cleanliness | Must be compatible with all engine oils and ATF fluids. Must not generate internal contaminants. |

Materials tested per?SAE J20, ASTM D471?compatibility standards.?Internal polishing and ultrasonic cleaning processes?ensure line cleanliness, protecting sensitive hydraulic components. |

3. Product Advantages

The automotive industry is evolving towards higher performance, longer life, lighter weight, and increased electrification, presenting new demands for oil cooler lines and highlighting the forward-thinking advantages of JIATIAN products.

High Performance & Heavy-Duty Use: Proliferation of turbocharged, high-output engines and increasingly severe operating conditions for commercial and off-road vehicles drive greater cooling demands.

Product Relevance: JIATIAN offers large-diameter (e.g., 12AN) lines and high-flow fittings to meet the cooling needs of large-displacement and high-load engines. Their anti-vibration construction is specifically designed for heavy-duty and off-road applications.

Lightweight & Integrated Design: Reducing component weight and space is key to improving efficiency.

Product Relevance: We employ high-strength aluminum alloy fittings and composite protective sleeves for significant weight reduction without compromising strength. Integrated quick-install kits pre-configure lines, fittings, and clamps, reducing installation space and complexity.

Extended Life & Low Maintenance: Users demand longer service intervals and overall vehicle lifespan.

Electrification Transition: Electric vehicle motors and power electronics also require cooling, often with different coolants and more challenging packaging.

Frequently Asked Questions?

Q1: Can JIATIAN lines replace OEM parts? Will it affect my warranty?

A1: Absolutely. JIATIAN oil cooler lines are manufactured to strict OEM specifications and often higher standards, offering multi-vehicle compatibility as direct OEM replacements. Installing high-quality replacement parts through proper channels typically does not void the vehicle's warranty for other components, but retaining purchase and installation records is advisable.

Q2: Which is better, metal bellows or rubber braided hose?

A2: Each has advantages depending on the application:

Metal Bellows (JIATIAN Core Strength): Higher temperature resistance, longer service life, superior vibration resistance, greater flexibility in routing. Better for tight spaces, high-vibration areas, or high-heat zones (e.g., near turbo).

Rubber Braided Hose: Offers flexibility and some vibration damping, generally more cost-effective, and easier to install. JIATIAN's versions use multi-layer reinforcement and premium compound rubber, far exceeding the performance of common market products.

Q3: What should I pay attention to during installation?

A3: ① Cleanliness: Ensure all connection ports are clean to prevent contamination. ② Alignment: Avoid sharp bends; ensure the line follows a natural path without rubbing against other components. ③ Torque: For threaded fittings, use a torque wrench and follow specifications – avoid over-tightening. ④ Inspection: After installation, start the engine, check oil pressure, and inspect all connections for leaks after a few minutes of idling. JIATIAN's quick-connect fittings greatly simplify installation and reduce error risk.

English

English