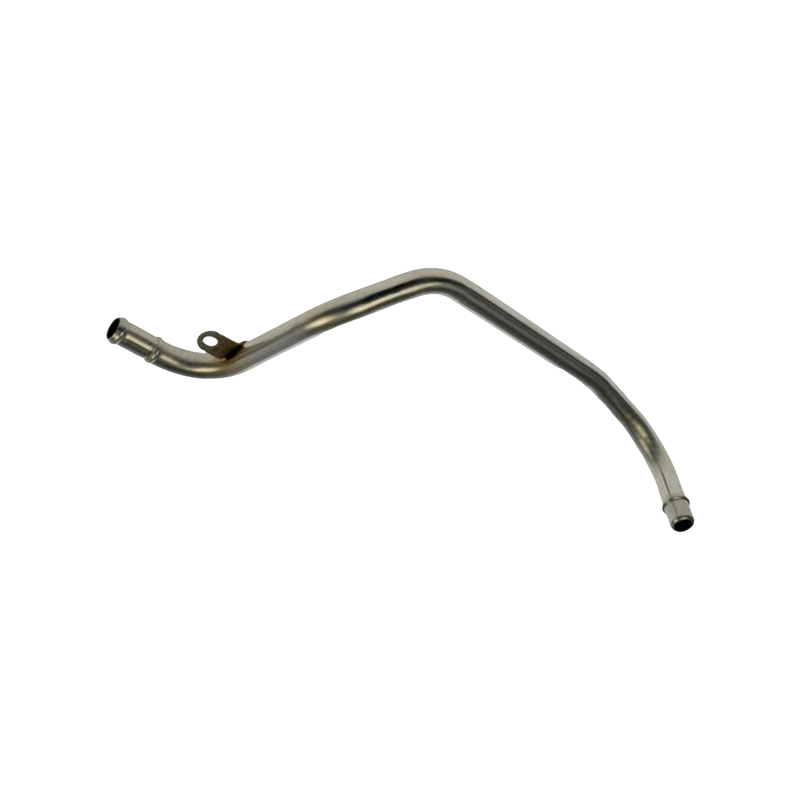

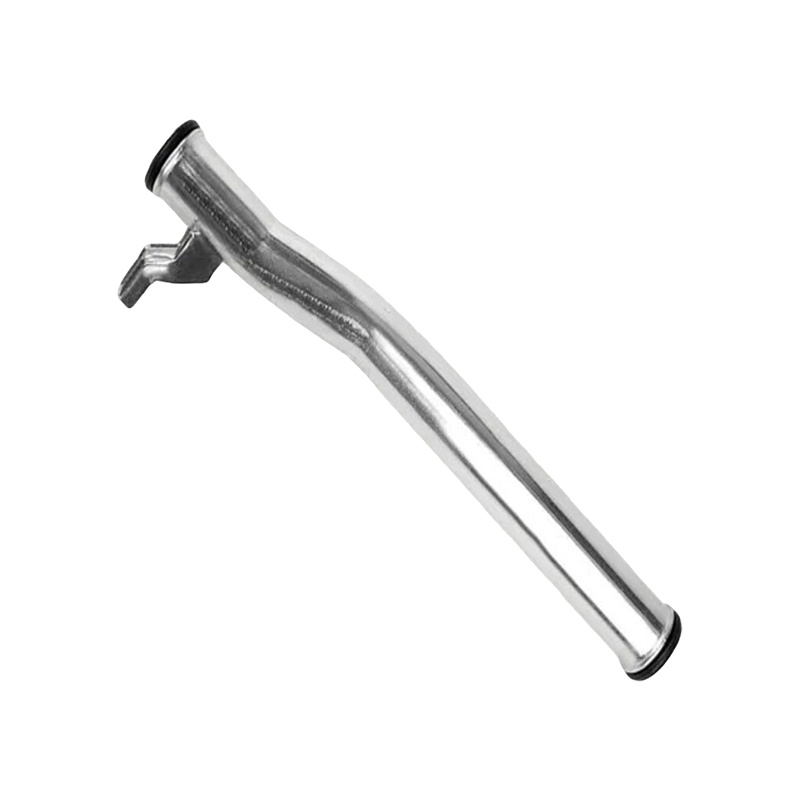

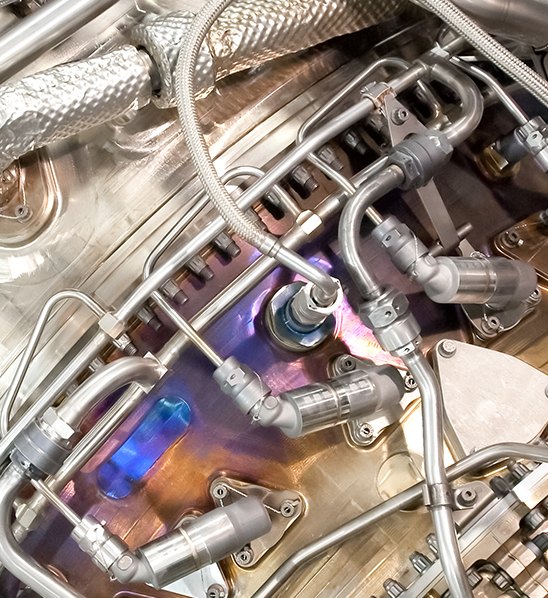

Engine Heater Hose Assembly

Engine Heater Hose Assembly

Engine Heater Hose Assembly

The Engine Heater Hose Assembly is an integrated piping assembly designed specifically for engine cooling/heating systems. It integrates high-temperature and corrosion-resistant hoses, clamps, Y-connectors (or other connectors), and necessary seals. It can directly replace original factory parts to achieve reliable circulation and heating of coolant inside the engine. This component is commonly used in the engine compartments of passenger cars, light commercial vehicles, and construction machinery to prevent coolant leaks, improve heat dissipation, and reduce the risk of engine overheating.

Product Features:

Includes all components, including hoses, clamps, and Y-connectors (or other fittings), allowing for a complete replacement in one go, saving time and effort.

Using heavy-walled steel pipe or aluminum alloy fittings with an oil- and corrosion-resistant coating, they resist rust and vibration and are suitable for high engine temperatures.

Equipped with O-ring or bellows ends, they ensure leak-free connections and maintain stable cooling system pressure.

Directly matches original equipment manufacturer specifications and can be used on a variety of vehicle brands.

Through reliable pipe connections, they ensure smooth coolant circulation within the engine, prevent local overheating, and protect engine life.

Using threaded or snap-on quick connectors and specialized clamps for easy installation, no additional tools or modifications are required.

Provides the same fit and durability as original equipment manufacturers, but at a more competitive cost.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

Engine overheating, coolant leaks, and pipe corrosion are persistent and stubborn issues in the automotive and construction machinery sectors. A minor pipeline failure can lead to expensive repairs or even engine seizure. Traditional piecemeal pipeline repairs often face challenges such as part incompatibility, complex installation, and insufficient durability. JIATIAN deeply understands these industry pain points and redefines cooling system maintenance standards with the?Integrated Engine Heater Hose Assembly—we don't just provide parts; we offer a?ready-to-install, long-lasting, and reliable?system-level solution.

Product Industry Knowledge System

Fundamental Understanding: Why is the Cooling System So Critical?

During normal engine operation, approximately one-third of the energy generated is in the form of heat. Without timely dissipation, this can lead to catastrophic failures like cylinder block deformation or piston seizure within minutes. The cooling system acts as the engine's "circulatory system," and its pipes are the crucial "blood vessels." Comparison of limitations in traditional repair methods vs. the JIATIAN integrated solution:

| Comparison Dimension | Traditional Piecemeal Repair | JIATIAN Integrated Hose Assembly |

|---|---|---|

| Part Completeness | Hoses, fittings, clamps purchased separately, high compatibility risk | Fully pre-assembled kit, ensuring system compatibility |

| Installation Efficiency | Requires on-site measuring, cutting, assembly (~1-3 hours) | Ready-to-install, saves ~60% installation time on average |

| Leak Risk Points | Multiple manual connection points, increased leak probability | Factory pre-tightened, standardized seals, reduces leak probability by >80% |

| Quality Control | Depends on technician's skill level | 100% pressure and leak tested before shipment |

?

Core Function:?

The JIATIAN Engine Heater Hose Assembly delivers three core functions:

-

Precise Flow Distribution: Optimized design with Y or multi-port connectors ensures balanced coolant flow between cylinders and the radiator, eliminating local hot spots.

-

Pressure Maintenance & Dampening: Special bellows sections and reinforced pipe walls absorb engine vibrations and maintain stable system pressure within the 1.5-2.0 bar operating range.

-

Temperature Adaptability: Maintains flexibility across a full temperature range of -40°C to 150°C, preventing brittle cracks in cold or softening in heat.

Core Performance:

Applied Material Science:

Pipe Body: Uses EPDM (Ethylene Propylene Diene Monomer) or Fluoroelastomer-based materials, offering up to 3x longer coolant corrosion resistance compared to standard rubber.

Fittings & Clamps: Heavy-wall steel or aluminum alloy fittings with surface coatings like zinc-nickel alloy or Dacromet process, passing salt spray tests exceeding 720 hours (industry standard is typically 240 hours).

Sealing Technology: Standard HNBR (Hydrogenated Nitrile Butadiene Rubber) O-rings or metal bellows sealing faces ensure seal integrity even after 200,000 thermal cycles.

Manufacturing Process Advantages:

Thanks to JIATIAN's in-house, industry-leading hydroforming bellows equipment and technology, we achieve:

One-piece forming of complex 3D pipe routing, reducing weld weak points and flow resistance.

Pipe wall thickness uniformity controlled within ±0.1mm.

Inner wall smoothness Ra ≤ 1.6μm, reducing deposits and flow resistance.

Product Highlights: Why Choose JIATIAN?

-

Fully Integrated, Worry-Free Replacement

-

Each assembly includes hoses, fittings, clamps, and seals—truly "ready out of the box."

-

Precision-matched to OEM interface dimensions and routing, requiring no on-site modification.

-

-

Military-Grade Durability Standards

-

Passes vibration test standard: SAE J1442 (≥100 hours).

-

Burst pressure ≥ 4 times working pressure, providing ample safety margin.

-

-

Wide Compatibility

-

Covers mainstream passenger cars, light commercial vehicles, and construction machinery from European, American, Japanese, Korean, and domestic brands.

-

Offers direct OEM part number cross-reference service.

-

-

Optimal Cost & Efficiency

-

Up to 20-35% lower procurement cost compared to genuine OEM parts.

-

Reduces installation labor time by 60%, significantly lowering total maintenance cost.

Backed by JIATIAN's Corporate Strength

Based in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City, with a 32,000 sq.m modern production base, JIATIAN has evolved from Ningbo Xingxin Metal Products Factory (established in 1995) into a?high-tech enterprise specializing in automotive pipe fittings manufacturing.

Our Manufacturing Capability Assurance:

-

10 CNC automatic pipe bending machines for precise, complex routing.

-

2 large brazing furnace assembly lines ensuring strong metallurgical bonds for metal fittings.

-

1 800T hydraulic hydroforming machine, leading the industry in large-diameter pipe forming capability.

-

4 welding robot sets + automatic laser welders, achieving 99.5% welding consistency.

-

In-house comprehensive laboratory implementing triple inspection for incoming materials, in-process, and finished goods.

Our Mission:?To create the world's leading automotive bellows with innovative technology and outstanding quality, ensuring every JIATIAN product performs reliably in extreme environments and promoting continuous progress in industry reliability and efficiency.

-

-

Frequently Asked Questions

Q1: How can I confirm the JIATIAN Hose Assembly matches my vehicle model?

We provide an online OEM part number cross-reference system. Simply provide the original hose part number or the first 8 digits of your vehicle's VIN to get the accurately matched JIATIAN product code. All assemblies are physically validated for 100% interface, length, and routing compatibility.

Q2: Are special tools or professional skills required for installation?

No. JIATIAN assemblies use quick-connect or threaded designs consistent with OEMs, along with dedicated clamps. Typically, only common wrenches are needed for installation. We provide illustrated installation guides and torque specifications for each product.

Q3: Can it be used in high-temperature or special coolant environments?

Yes. Our standard products are compatible with ethylene glycol-based coolants. For heavy-duty, high-boost engines or special coolants (e.g., OAT technology), we offer a?High-Temperature Enhanced Version?made from fluoroelastomer and stainless steel fittings, capable of withstanding peak temperatures up to 180°C continuously.

Q4: Compared to other aftermarket parts, what is JIATIAN's core advantage?

Beyond material and process advantages, our?integrated design and fully controlled manufacturing process?are key. From raw materials to finished product, everything is completed in our own factory, eliminating quality variances from outsourcing. Our hydroforming technology allows for fewer connectors, reducing potential leak points—an achievement many competitors cannot match.

?

English

English