Transmission Oil Cooler Pressure Line

Transmission Oil Cooler Pressure Line

Transmission Oil Cooler Pressure Line

information to be updated

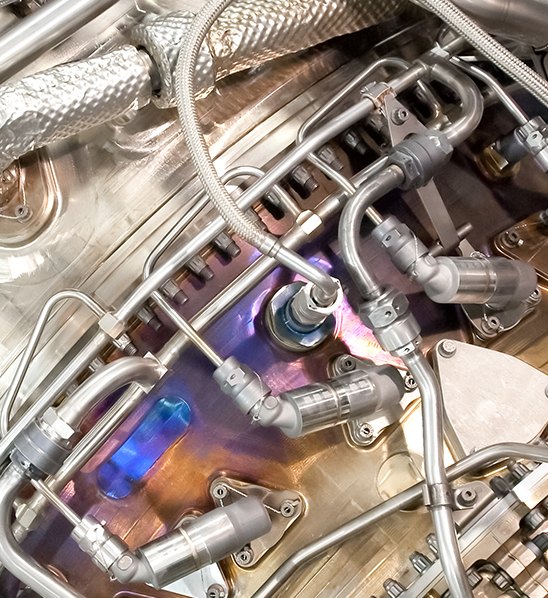

The Transmission Oil Cooler Line transfers hot oil generated inside the transmission to a cooler and then returns the cooled oil to the transmission, ensuring the oil temperature remains within a safe operating range, thereby extending transmission life and reducing fuel consumption.

Product Features:

1. Stainless Steel Braided Outer Layer + PTFE (Teflon) Inner Liner

This line utilizes a 304 stainless steel braided layer wrapped around a PTFE extruded core tube, offering high-temperature and corrosion resistance, flexibility, and low pressure drop. It maintains structural integrity even at high temperatures (+150°C) to prevent oil leaks. Its flexible design facilitates routing in confined spaces.

2. Multiple sizes available to meet the needs of various vehicle models and transmission layouts.

3. Anti-vibration and Anti-noise Design

A damping structure within the braided layer and hose reduces noise and vibration caused by oil pump pulsation, improving vehicle NVH performance.

4. Material Options

In addition to stainless steel, special versions such as aluminum/copper braided and all-stainless steel rigid tube are also available to meet extreme high-pressure or lightweighting requirements.

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

In today's automotive industry trend towards higher efficiency and lightweight design, the transmission, as the core component of power transfer, has seen its thermal management become a critical factor affecting overall vehicle performance, lifespan, and fuel consumption. Traditional rubber cooling lines are prone to aging and cracking under high temperature and pressure, while ordinary metal lines face challenges of vibration noise and limited layout flexibility. With nearly three decades of experience in automotive pipe fitting manufacturing, JIATIAN has developed a new generation of?Stainless Steel Braided PTFE Transmission Oil Cooler Lines?to address these industry pain points. Through innovative materials and structural design, we are redefining the performance standards for cooling lines.

Basic Understanding: The Importance of the Transmission Oil Cooling System

Transmission oil temperature can exceed 120°C during operation. Overheating causes oil degradation, reduced lubrication performance, accelerated wear, increased fuel consumption, and even system failure. The cooling lines act as the "circulatory system" for the transmission. Their reliability and efficiency directly determine the transmission's lifespan and the vehicle's overall energy efficiency.

| Traditional Line Type | Main Limitations | Potential Consequences |

|---|---|---|

| Rubber Hose | High-temperature aging, permeation, limited pressure resistance | Leaks, periodic replacement, performance degradation |

| Ordinary Metal Hard Line | Vibration transfer, limited installation layout options | High noise, fatigue fracture, poor adaptability |

| Low-cost Braided Line | The inner layer material is not resistant to high temperatures/corrosion. | Fluid contamination, line blockage, failure risk |

?

JIATIAN Solution: Utilizes a composite structure of 304 stainless steel braiding + PTFE (Polytetrafluoroethylene) inner liner, combining the strength of metal with the chemical stability of polymer.

Core Function: Ensuring Efficient and Reliable Heat Exchange

Our cooler lines are designed specifically for efficiently transferring hot transmission oil (up to 150°C+) to ensure fluid moves rapidly and with low resistance through the cooler, enabling stable temperature control.

Core Performance Data Comparison

| Performance Indicator | JIATIAN Stainless Steel Braided PTFE Line | Traditional Rubber Hose | Ordinary Metal Line |

|---|---|---|---|

| Long-term Temp. Range | -40°C to +150°C (Peak up to 200°C) | -30°C to +125°C | -40°C to +150°C |

| Working Pressure | Up to 3.0 MPa (Higher available custom) | Typically <1.5 MPa | High, but susceptible to vibration |

| Fluid Compatibility | Excellent (PTFE resists all transmission fluid corrosion) | Good, but may swell or permeate | Excellent |

| Bending Fatigue Life | >1,000,000 cycles (Flexible design) | ~500,000 cycles | Low (Hard line unsuitable for frequent bending) |

| Weight (Same Spec Comparison) | Medium (Can be optimized for lightweight) | Light | Heavy |

Product Highlights & JIATIAN Manufacturing Advantages

-

Applied Materials Science:

-

Inner Liner: Food-grade extruded PTFE inner tube, extremely smooth surface with very low friction coefficient, reduces fluid flow resistance (low pressure drop), improves cooling efficiency, and prevents internal delamination from contaminating fluid.

-

Reinforcement Layer: High-density 304 stainless steel braiding provides excellent burst pressure resistance and radial support, preventing line expansion/deformation under high pressure.

-

-

Unique NVH (Noise, Vibration, Harshness) Control:

The line incorporates an internal damping structure that effectively absorbs vibrations from pump pulsation and engine transmission, reducing related noise by?over 30%?compared to traditional hard lines, enhancing driving quietness. -

Flexible Customization Capability:

-

Full Size Range: Custom diameters from ¢10mm to ¢80mm and various lengths available to meet needs from passenger cars to commercial vehicles.

-

Material Diversity: Besides the standard stainless steel braided version, we also offer?Aluminum/Copper Braided?versions for ultimate lightweight goals, or?All-Stainless Steel Hard Line?versions for extreme high-pressure/high-temperature environments.

-

-

Backed by JIATIAN Manufacturing Strength:

All products originate from our modern production base in Ningbo (32,000㎡ facility). Leveraging?10 CNC fully automatic pipe bending machines,?large brazing furnace assembly lines, industry-leading?hydraulic internal high-pressure forming machines (max. length 1.5m)?and?800T hydraulic hydroforming machines, we ensure dimensional accuracy and structural consistency for every pipe fitting.?Fully automatic laser welders and welding robots?guarantee joint strength and sealing integrity. Our in-house?comprehensive laboratory?conducts rigorous tests on products, including pulse pressure, burst pressure, thermal cycling, and salt spray corrosion, ensuring reliability upon delivery.

Frequently Asked Questions (FAQs)

Q1: Why choose a PTFE inner liner over rubber?

A1: PTFE (Polytetrafluoroethylene) possesses chemical inertness unmatched by rubber. It does not react with the transmission fluid being transferred, preventing swelling or permeation. It can withstand higher continuous operating temperatures (150°C vs. 125°C), resulting in longer service life and lower maintenance requirements.

Q2: Will the stainless steel braiding rust?

A2: We use AISI 304 stainless steel (or 316 upon request), which offers excellent corrosion resistance. It provides long-term rust protection in standard automotive underbody environments (exposure to rain, salt spray, etc.). We can also provide additional surface coatings for more severe environments.

Q3: What should be noted during installation?

A3: Our lines offer good flexibility for routing in confined spaces. However, avoid contact with sharp edges or excessive bending (we provide minimum bend radius recommendations). It is recommended to use hose clamps designed specifically for stainless steel braided lines and ensure fittings are tightened to the specified torque.

Q4: Can these lines be adapted to my existing vehicle or modification project?

A4: Absolutely. Customization is one of JIATIAN's core strengths. With our powerful R&D and processing centers, we can design and manufacture fully compatible cooler line assemblies based on your provided fitting specifications, spatial layout, and performance requirements.

Q5: Compared to buying OEM parts directly, what are the advantages of JIATIAN products?

A5: OEM parts are often designed with cost and mass production as primary drivers. JIATIAN specializes in the high-performance pipe fitting sector. We use superior material combinations (e.g., PTFE + Stainless Steel), placing greater emphasis on durability, performance optimization (e.g., low-pressure loss, NVH control), and customized solutions. Our products often deliver performance and longevity that exceed OEM standards.

?

English

English